Precision CNC machining (Computer Numerical Control) refers to the use of computer-controlled machines to manufacture parts with high accuracy and repeatability. CNC systems interpret programming code and convert it into precise mechanical movements, allowing machines and tools to manufacture components with exceptional detail and minimal deviation. Compared to traditional manual machining, CNC offers superior consistency, accuracy, and the ability to create complex geometries that are nearly impossible to achieve otherwise.

Key Factors That Affect CNC Precision Machining Accuracy

Achieving high precision in CNC machining is influenced by both machine-related and external factors:

Machine-Related Factors:

- Tool Path Optimization: Precise control of the tool path minimizes errors and improves dimensional accuracy.

- Tool Quality: High-quality cutting tools are essential for achieving clean edges and tight tolerances.

- Raw Material Quality: Material uniformity and integrity impact machining consistency.

- Coolant and Lubricant Performance: Proper coolant reduces thermal distortion and extends tool life.

External Environmental Factors:

- Ambient Temperature and Humidity: Fluctuations can cause material expansion or contraction.

- Chip Removal and Dust Control: Efficient chip evacuation prevents tool interference and surface defects.

- Fire Safety and Cleanliness: Contaminants and safety risks can disrupt operations and impact finish quality.

Best Practices to Improve CNC Precision Machining Accuracy

To achieve superior results in CNC precision machining, manufacturers should follow a strict set of operational protocols:

- Tool Selection: Use dedicated cutting tools for different materials, and never mix tools across incompatible materials.

- Clean Setup: Ensure that tools and holders are cleaned thoroughly before installation.

- Environmental Control: Maintain a stable environment with controlled temperature and humidity to minimize thermal expansion.

- Accurate Clamping and Calibration: Use dial indicators to check for fixture alignment and verify part positioning with calipers.

- Use Specialized Coolants: Inject proper coolant fluids to reduce friction and maintain dimensional stability.

- Optimize Tool Paths: Strategically plan cutting paths to reduce unnecessary movement and improve machining efficiency.

- Standardize CNC Programming: Organize and document CNC program files clearly for consistency and easy management.

- Control Spindle and Feed Speeds: Adjust spindle speeds and feed rates based on the region of the workpiece and material properties.

- Post-Machining Inspection: Conduct thorough quality checks before removing the part from the machine.

By implementing the above practices, manufacturers can consistently deliver high-precision components and improve the overall reliability of their precision machining services.

Conclusion

Precision CNC machining is a complex process that requires attention to detail in every step—from tool selection and environmental control to programming and inspection. By understanding and managing the factors that influence accuracy, manufacturers can provide superior CNC precision machining services that meet the highest standards in industries like aerospace, medical, and automotive.

Our Advanced CNC Machining Equipment

We operate with state-of-the-art machines to deliver high-performance precision CNC machining. Our facility is equipped for both prototyping and full-scale production.

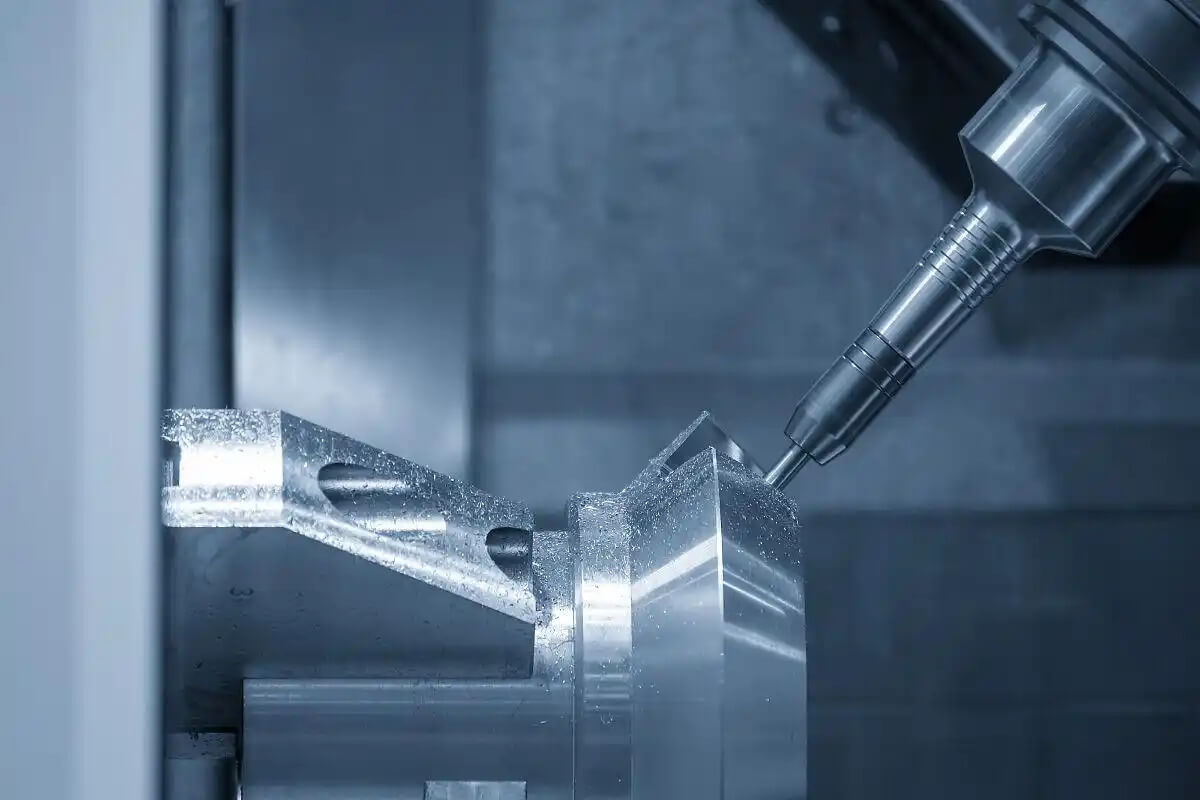

5-Axis CNC machine used for high-precision component machining

CNC lathe machine producing precision round parts for aerospace and medical use

Vertical machining center for multi-axis CNC precision machining services

Automated CNC production line improving efficiency and consistency in precision machinin

Ready to Start Your Precision CNC Project?

We specialize in CNC precision machining for industries that demand tight tolerances and high reliability. Whether you need prototyping or mass production, we’re here to help.