What Are CNC Machining Tolerances?

CNC machining tolerances refer to the acceptable deviation in a part’s dimensions. Defined as ±X mm or ±X inch, tolerances determine how much a part’s size can differ from its design specifications. Achieving precise tolerances is essential for fit, function, and performance, especially in industries such as aerospace, medical, and robotics.

1. Typical tolerance ranges

General machining tolerances:

✅ General Tolerance:

±0.05mm to ±0.2mm (depending on equipment and process).

✅ High-Precision Machining:

± 0.01mm to ±0.05mm (such as precision molds, aerospace parts).

✅ Ultra-Precision Machining:

± 0.001mm to ±0.005mm (e.g. optics, medical implants).

2. Different materials tolerance

✅ Metallic materials (e.g. aluminum, steel):

General milling/turning: ±0.05mm to ±0.1mm.

High-precision machining (e.g. 5-axis linkage): ± 0.01mm to ±0.02mm.

✅ Plastic materials (e.g. PEEK, nylon):

Normal machining: ± 0.1mm to ±0.2mm.

Precision machining: ±0.05mm to ±0.1mm.

✅ Composites (e.g. carbon fiber):

Tolerances are wide, typically ±0.1mm to ±0.3mm.

3. different processing methods Tolerances

✅ Milling:

Face milling: ±0.05mm to ±0.1mm.

Milling of complex surfaces: ± 0.1mm to ±0.2mm.

✅Turning:

External turning: ± 0.01mm to ±0.05mm.

Internal turning: ±0.02mm to ±0.08mm.

✅Drill:

Normal drilling: ± 0.1mm to ±0.2mm.

Precision drilling (e.g. deep hole drilling for aviation): ± 0.01mm to ±0.05mm.

4.Factors that affect tolerances

✅ Factors of the equipment itself

✅CNC cutting tool factor

✅CNC parts form factor

✅Processing environmental factors

✅Material factors

Our CNC Tolerance Capabilities

We support both ISO 2768-m (medium) and ISO 2768-f (fine) standards. Custom tolerances based on drawings are also accepted.

3. CNC Tolerances by Machining Process

Tolerances of different machining methods

| Process | Typical Tolerance Range |

| Face Milling | ±0.05mm – ±0.1mm |

| Complex Surface Milling | ±0.1mm – ±0.2mm |

| External Turning | ±0.01mm – ±0.05mm |

| Internal Boring | ±0.02mm – ±0.08mm |

| Standard Drilling | ±0.1mm – ±0.2mm |

| Precision Deep Hole Drilling | ±0.01mm – ±0.05mm |

Balancing Cost & Precision

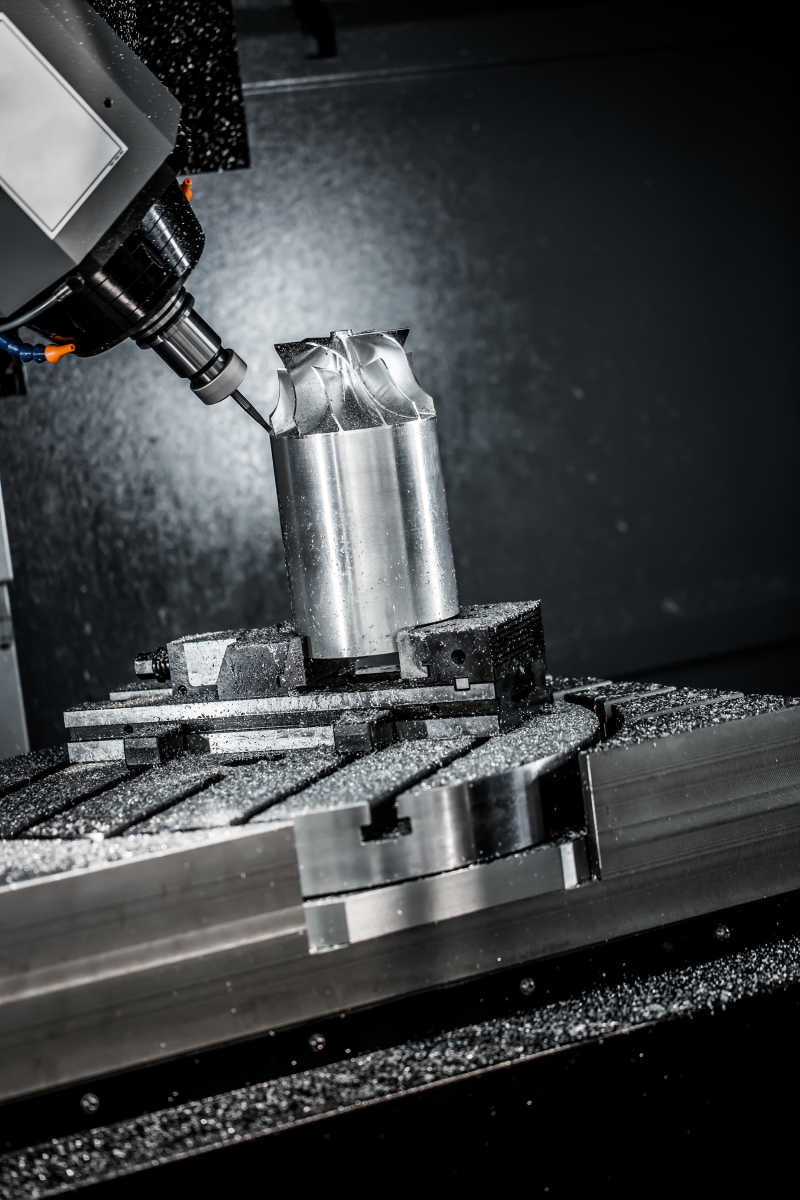

Gallary of Tight-Tolerance CNC Parts

We deliver high-accuracy CNC machined components with tolerances from ±0.2mm to as tight as ±0.001mm. Whether you need general machining or ultra-precision components, we have the capabilities to meet your tolerance requirements.

CNC Machining Tolerances – FAQ

Standard CNC machining tolerances are typically ±0.127 mm (±0.005″). For general applications, this tolerance ensures parts fit and function correctly. Tighter tolerances are available for precision machining needs.

High-precision CNC machines can achieve tolerances as tight as ±0.005 mm (±0.0002″). However, achievable tolerances depend on factors like material, machine type, and part geometry.

±0.01mm tolerance means the actual size of the part can vary by 0.01mm above or below the specified dimension. In CNC machining, this level is considered a tight or precision tolerance.

Yes. Materials like plastics may expand or shrink more during machining compared to metals like aluminum or steel, so tolerances may need adjustment based on material behavior.

For aluminum CNC machining, tolerances of ±0.01 mm to ±0.05 mm are typically achievable, depending on part complexity and equipment. Tight tolerances may require precision setups and quality control.

You can, but cost and feasibility depend on the design, material, and machining limits. We recommend practical tolerances where possible.

Yes, tighter tolerances often require additional processes such as slower cutting speeds, multiple passes, special tools, or extra quality checks, which may increase costs and lead time.

We ensure tolerance accuracy through precision machines, skilled operators, calibrated inspection tools, and strict quality control processes. Inspection reports are available upon request.

We follow international standards such as ISO 2768 and ASME Y14.5 for CNC machining tolerances. If your project requires specific compliance, please indicate it in your drawings.

General CNC tolerances (e.g., ±0.1 mm) are suitable for non-critical parts, while precision tolerances (e.g., ±0.01 mm or tighter) are used for high-performance or assembly-critical parts.

Yes, plastics typically have looser tolerances due to flexibility and thermal expansion (e.g., ±0.1mm or more).