CNC Machining Experience. Our extensive experience ensures precision, reliability, and unmatched quality in every project.

Quick Quote. Get fast, accurate quotes within 4 hours during business hours, keeping your project on track.

From a single prototype to large-scale production, we manufacture with flexibility to meet your needs.

Our CNC machining serves nearly every sector with tailored solutions.

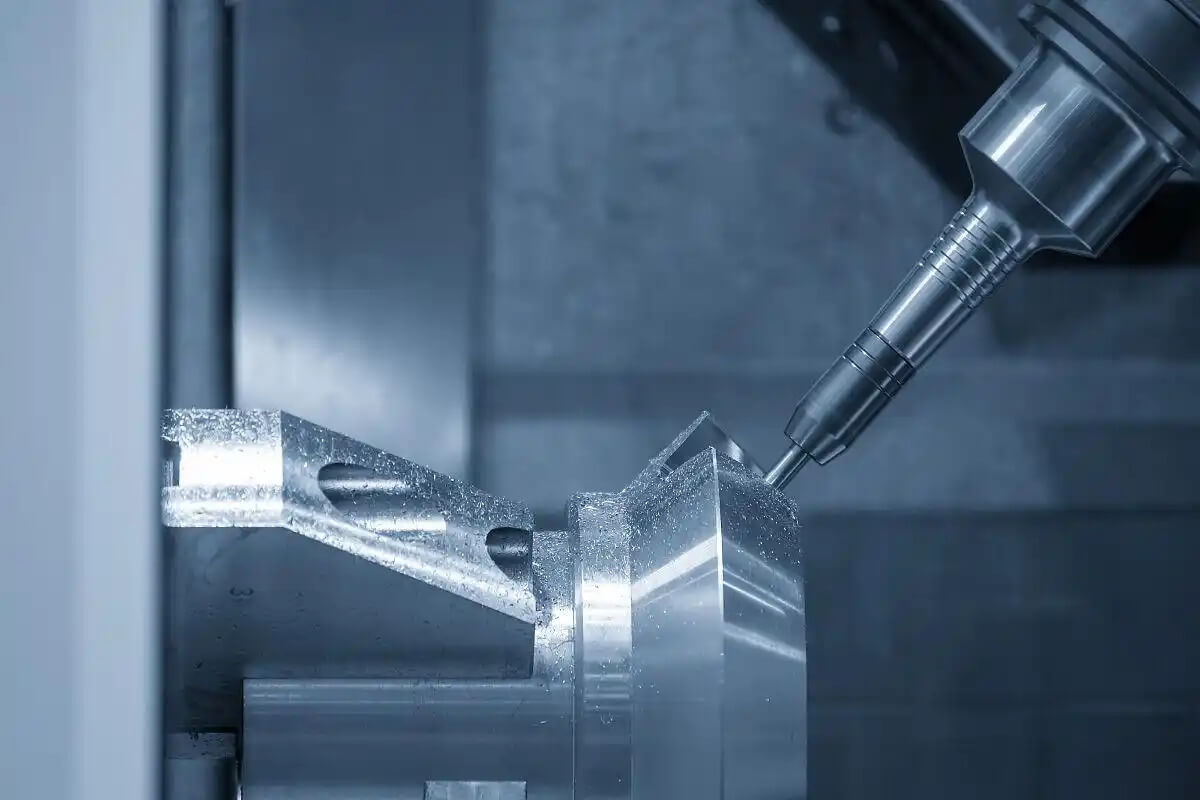

Custom 5 Axis CNC Machining Services

We specialize in custom 5 Axis CNC machining services, delivering ultra-precise components with tight tolerances up to ±0.01mm and surface roughness as fine as Ra 0.2μm. Designed for high-precision part manufacturing across industries such as aerospace, automotive, medical, robotics, and electronics, we support both low-volume prototyping and high-volume production — from 1 to 10,000+ pieces.

Our 5 Axis CNC Machining Services deliver high-precision custom parts with ±0.01mm tolerances and Ra0.2μm surface finishes. We support custom orders from 1 to 10,000+ pieces with fast turnaround, powered by 100+ CNC machines running 24/7 in our own facility. Every part is inspected through a strict 12-step quality control process. You also get 1-on-1 engineering support and access to 40+ certified materials and 20+ surface finishing options — ensuring your parts meet exact specifications, every time. Let us bring your complex designs to life with speed, precision, and reliability. Request a quote today and experience true high-performance machining.

Custom 5 Axis CNC Machining Services

Our Custom 5 Axis CNC Machining Services are designed for the most complex and high-precision parts. With simultaneous multi-axis movement, our 5-axis machines can machine intricate geometries in a single setup — significantly reducing lead time and improving accuracy.

Key Features:

✅True 5-axis simultaneous machining.

✅Custom milled parts for prototyping and production.

✅Tolerances up to ±0.01mm, Ra0.2μm surface finish.

✅Ideal for aerospace, medical, robotics, and automotive industries.

✅Fewer setups, faster cycle times, and better surface quality.

✅Quick turn milling services. Perfect for undercuts, deep cavities, and complex contours.

Custom 3+2 Axis CNC Machining Services

Our Custom 3+2 Axis CNC Machining Services provide a cost-effective solution for moderately complex parts. This method allows the workpiece to be positioned in five axes, but machining occurs in 3 axes at a time. It enables more flexible part orientation and better accessibility without requiring full 5-axis capabilities.

Key Features:

✅ 3-axis cutting with two additional positioning axes. Custom machined parts for prototyping and production.

✅ More affordable than full 5-axis for certain geometries.

✅ Excellent for multi-face machining and angular features. Quick turn machining services.

✅ Ideal for fixtures, housings, enclosures, and mechanical components.

✅ High repeatability with reduced repositioning errors.

Why Choose Our 5 Axis CNC Machining Services?

LOW MOQ

On-Demand Manufacturing: Rapid production from 1 to 10,000 pieces.

Hight Precision

Tight Tolerances & Fine Surface Finishes: Up to ±0.01mm accuracy, Ra0.2μm finish.

Rapid Turnaround

Prototypes in 1 day, delivered to US & Europe in 5-7 days.

Quality Control

12-step inspection process, fully equipped in-house lab.

Engineering Support

1-on-1 Engineering Support: From DFM to final delivery.

Material & Surface

40+ certified materials, 20+ finishing choices.

Global Expertise

Serving 500+ clients in aerospace, medical, and automotive industries.

What is 5 Axis CNC Machining?

5 Axis CNC Machining refers to the use of CNC equipment that can move a part or cutting tool along five different axes simultaneously — typically X, Y, Z, and rotational axes A and B. This advanced capability allows for the production of highly complex, multi-surface parts with fewer setups, tighter tolerances, and improved surface finishes. Our global CNC machining services utilize advanced 5 Axis CNC Machining to produce intricate components for industries such as aerospace, medical, and automotive. Serving clients across the US and Europe, we provide high-precision custom parts with fast lead times — typically delivered globally within 5–7 days.

Our 5 Axis CNC Services

✅ Rapid Prototyping: From CAD to part in 1 day.

✅ Low-Volume Production: Flexible MOQ for custom parts.

✅ High-Volume Manufacturing: Scalable production with ±0.0003” tolerances.

✅ Custom Machining: Tailored solutions for complex designs.

Materials for 5 Axis CNC Machining

According to your design requirements, we have a variety of different CNC materials for you to choose from to meet your customized five-axis CNC machining needs. From high-precision metals to engineering plastics, our CNC machining team ensures that each material can achieve perfect processing results.

| Material Type | Examples | Applications |

| Metals | Aluminum, Titanium, Stainless Steel | Aerospace, Automotive |

| Plastics | ABS, POM, Nylon | Medical, Electronics |

| Composites | Carbon Fiber | Energy, Aerospace |

Aluminum

Stainless Steel

Titanium

Brass

ABS

Carbon Fiber

Polycarbonate

Acrylic

Hard Plastic

Custom 5 Axis CNC Machining Surface Finishing Options

We provide a wide range of surface finishing solutions to improve the performance and aesthetics of 5-axis CNC machined parts. These finishes enhance properties such as texture, hardness, smoothness, chemical resistance, and corrosion resistance. In addition to improving functionality, they effectively conceal tool marks left by the machining process, resulting in a clean, high-quality appearance. Below are some of the most commonly used finishing options:

As Machined

CNC machined metal, natural color, no need for any surface treatment.

Sand Blasting

Cleans the CNC Machining Parts surface and increases the roughness to improve the adhesion of the coating.

Electropolishing

Smooths the surface through electrochemical dissolution, suitable for parts with complex shapes.

Anodizing + Dyeing

Used for surface treatment of metal materials such as aluminum alloy to enhance their decorative properties and corrosion resistance.

Anodizing

Applicable to aluminum-titanium-magnesium alloys, forming an oxide film to enhance corrosion resistance and hardness, such as hard oxidation (Type III) for aviation parts.

Passivation

Make the surface of CNC machined metal parts inactive, thereby slowing down the corrosion rate of the metal.

Polishing

Polishing CNC machined parts improves surface smoothness, removes tool marks, enhances assembly fit, increases corrosion and wear resistance, and elevates overall appearance.

Brushing

Brushing forms linear textures and is used for electronic product housings.

Powder Coating

Curing after electrostatic spraying provides a variety of colors and wear-resistant surfaces.

Laser Marking

Use laser to engrave information such as marks, text, patterns, etc. on the surface of the material onto the object. Applicable to metal, plastic, ceramic, glass, etc.

Industries and Applications of 5 Axis CNC Machining

Industries our global CNC machining services are suitable for:

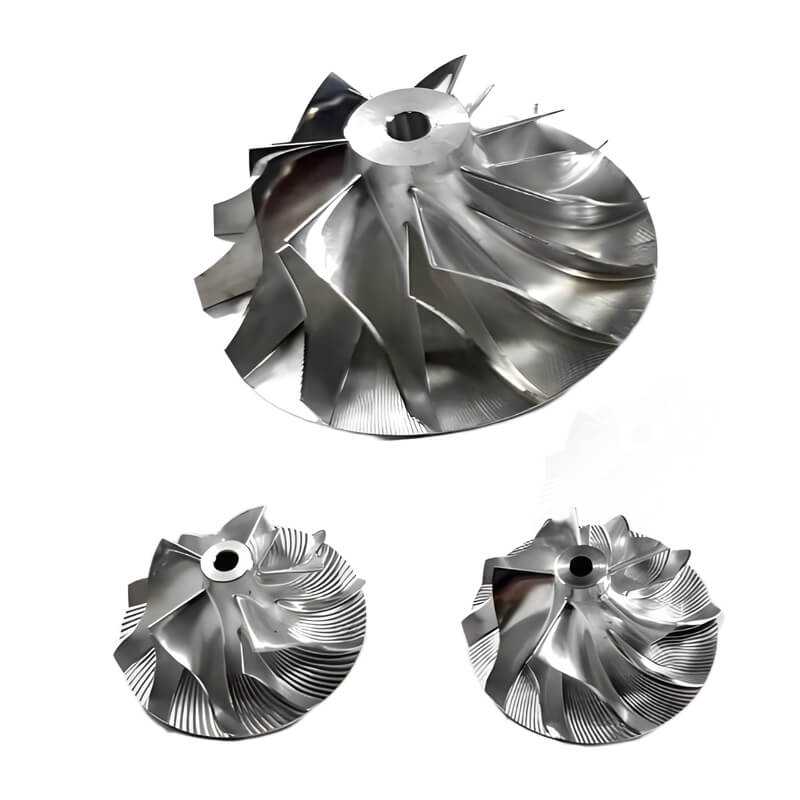

Aerospace

Turbine blades, engine housings, structural components. Landing gear parts, wing fittings, Satellite and UAV precision components

Medical Devices

Orthopedic implants (e.g., knee and hip replacements). Surgical instruments, dental tools. Customized prosthetics and medical fixtures

Automotive

Engine components, transmission housings. Injection mold tooling for interiors/exteriors. High-performance and motorsport parts.

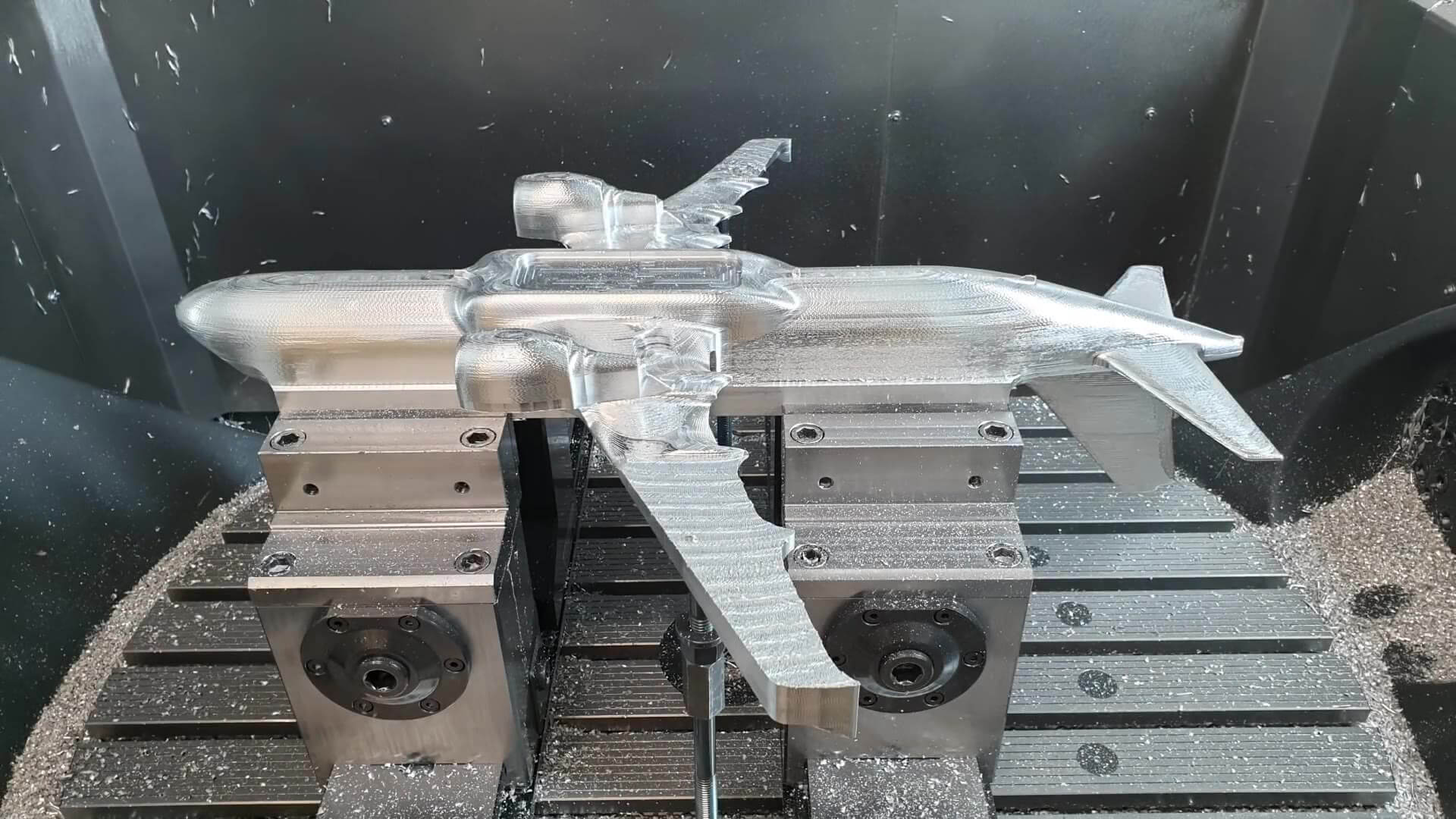

Gifts & Crafts

Various models, souvenirs, and doll toys

Energy

Gas turbine parts, wind turbine blade molds, Drilling equipment components, nuclear power parts

Precision Molding

Injection molds, die casting molds, rubber molds,Micro-structured cavities and complex flow channels

Industrial Automation & Robotics

Joint housings, robotic end-effectors, High-precision jigs, fixtures, and toolings

Electronics & Consumer Devices

Heat sinks, connectors, structural housings, Precision frames for smartphones and smart devices

5 Axis CNC Machining Parts Gallery

Below is a small selection of 5 axis CNC machining prototypes and end-use parts we produce for our customers. Used with permission.

From Design to Global Delivery with 6 Simple Steps

As a custom five-axis CNC machining manufacturer, we provide CNC parts production and rapid prototyping services.

5 Axis CNC Machining FAQs

It allows for complex geometries, reduces setup time, and improves precision compared to 3-axis machining.

MOQ: 1, whether it is a custom 5 Axis CNC machining prototype or low volume production, it is supported.

Our global delivery CNC machining services ship precision parts to the US and Europe in 5-7 days, with prototypes ready in 1 day.

Costs depend on material, complexity, and volume. Upload your CAD file for a quote in 4 hours.

We machine aluminum, titanium, stainless steel, ABS, POM, and more.

Yes, we do sign a non-disclosure agreement (NDA) to protect the design drawings from being leaked. The drawings are kept by the business department and are strictly confidential. Only disassembly drawings are used internally (except for those that cannot be disassembled), and sharing videos and pictures on public platforms is prohibited. We always put customer information security first. If you have other needs, please feel free to ask, and we will provide a customized confidentiality plan.

What Our Clients Say

“Their global CNC machining services reduced our lead time by 30%. Exceptional quality!”

John Doe

US Aerospace Engineer

“Fast quotes and reliable delivery to Europe. Highly recommend for medical parts.”

Jane Smith

European Medical Device Manufacturer

They provided detailed design support and rapid CNC machining prototyping for our new product. If you are looking for a reliable company for custom CNC machining parts, I highly recommend their CNC services.

Mary Taber

Senior Product Designer

Get Started with Your 5-Axis CNC Project