About our CNC Stainless Steel Machining Manufacturing

We are a leading China-based CNC stainless steel machining factory specializing in precision stainless steel parts. With state-of-the-art CNC equipment and a skilled team, we provide custom stainless steel components for industries like aerospace, medical, automotive, and energy worldwide. Our mission: Deliver superior quality and value to global clients.

The process is suitable for a wide range of stainless steel grades such as 201, 202, 301, 304, 316, 410, 420 and 430, etc depending on the required strength, weight, and corrosion resistance. With the help of multi-axis CNC equipment, stainless steel parts can be machined into intricate shapes for critical applications.

Industries We Serve with CNC Stainless Steel Components

- Medical devices and surgical equipment

- Food and beverage processing machinery

- Marine and offshore systems

- Automotive and motorsports

- Industrial automation and robotics

Showcase of CNC Stainless Steel Machining Parts

Custom CNC Stainless Steel machining for 316 food Machine

Machined Stainless Steel parts for automotive industry

CNC Machined Stainless Steel Equipment Brackets

Stainless Steel CNC parts for electronics

Machined Aluminum parts

cnc aluminum parts for automotive industry

CNC Stainless Steel machining Prats

CNC Stainless Steel parts for electronics

Your One-Stop Custom CNC Stainless Steel Machining Solution

Machining Capabilities for CNC Stainless Steel

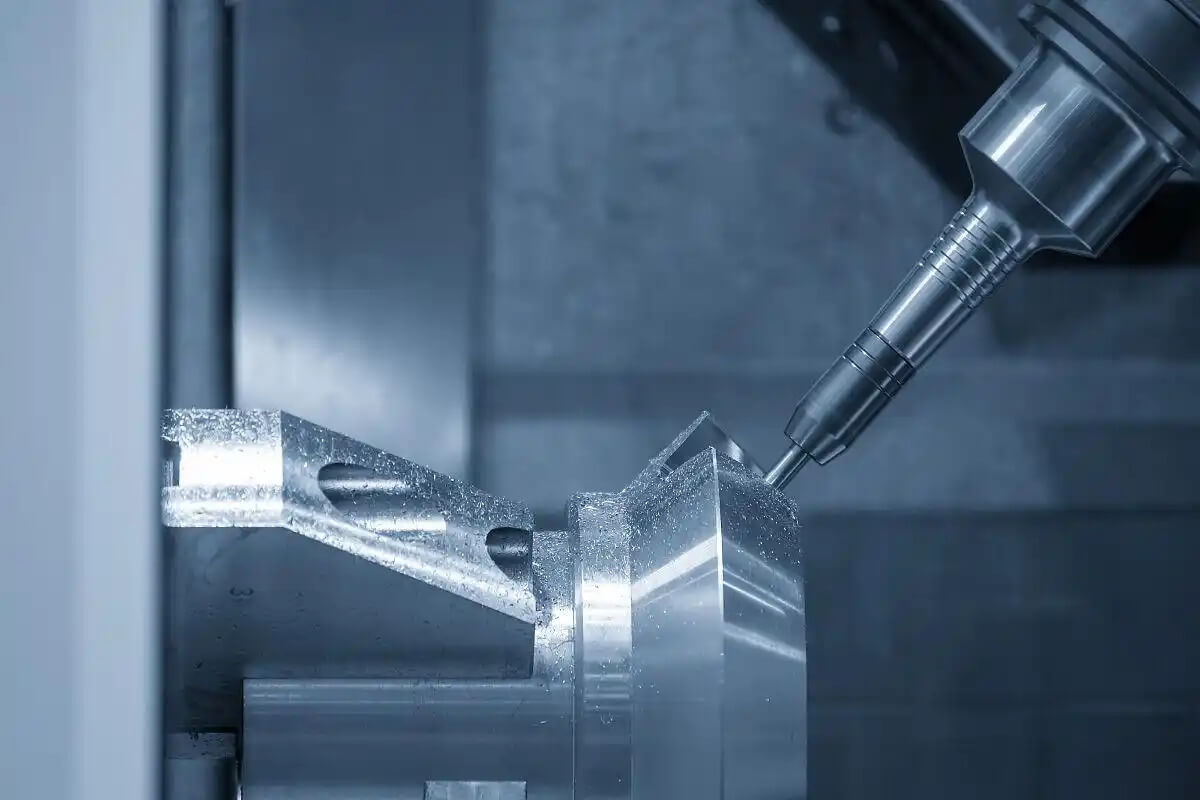

Our CNC machining capabilities cover everything from simple stainless steel milling to complex 5-axis machined components.

5 Axis CNC Machining Center

5 Axis Stainless Steel CNC Machining

✅Main advantages: High accuracy, fewer setups, excellent for aerospace and medical parts.

✅Best for: Complex curved surfaces, undercuts, multi-face components.

3+2 Axis CNC Machining Center

3+2 4 Axis Stainless Steel CNC Machining

✅ Main advantages: Cost-effective alternative to full 5-axis machining.

✅Best for: Parts requiring angled features without full simultaneous motion.Cost-effective machining parts.

CNC Milling

CNC Milling with live tooling.

✅Main advantages: High-speed, tight tolerance, versatile material compatibility.

✅Best for: Precision housings, structural components, brackets.

CNC Lathes (Turning Centers)

CNC Turning with live tooling..

✅ Main advantages: Excellent for cylindrical parts and high-volume production.

✅ Best for: Shafts, bushings, fasteners, fittings

CNC Drilling Machines

Threading, tapping, and deep hole drilling.

✅Main advantages: Consistent hole depth and diameter, tight tolerance control.

✅Best for: Bolt holes, tapped holes, deep hole drilling.

Available Stainless Steel Materials

We stock and process a wide range of Stainless Steel grades suitable for CNC milling, turning, and finishing.

| Stainless Steel Type | Representative Grades | Core Characteristics | Main Applications |

| Austenitic | 304/316 | Non-magnetic, highly corrosion-resistant, ductile, weldable. 316 (with Molybdenum) is best for chlorides. | Food, medical, architecture, chemical processing. |

| Ferritic | 430/409 | Magnetic, good corrosion resistance, lower cost. 409 is common in automotive exhaust. | Appliances, kitchenware, automotive exhaust. |

| Martensitic | 410/420/440C | Magnetic, high strength/hardness after heat treatment, moderate corrosion resistance. | Knives, surgical tools, bearings, industrial parts. |

| Duplex | 2205/2507 | High strength, excellent resistance to stress corrosion and pitting (even in harsh chloride). | Oil & gas, chemical processing, marine environments. |

| Precipitation Hardening (PH) | 17-4PH | Extremely high strength, good corrosion resistance, heat-treatable. | Aerospace, nuclear, high-strength industrial components. |

Stainless Steel

Different Stainless Steel grades for CNC machining

Surface Finishing Options for Stainless Steel CNC Parts

We offer a wide range of finishing services to enhance the functionality and appearance of aluminum CNC parts.

As Machined

CNC machined metal, natural color, no need for any surface treatment.

Sand Blasting

Cleans the CNC Machining Parts surface and increases the roughness to improve the adhesion of the coating.

Electropolishing

Smooths the surface through electrochemical dissolution, suitable for parts with complex shapes.

Anodizing + Dyeing

Used for surface treatment of metal materials such as aluminum alloy to enhance their decorative properties and corrosion resistance.

Anodizing

Applicable to aluminum-titanium-magnesium alloys, forming an oxide film to enhance corrosion resistance and hardness, such as hard oxidation (Type III) for aviation parts.

Passivation

Make the surface of CNC machined metal parts inactive, thereby slowing down the corrosion rate of the metal.

Polishing

Polishing CNC machined parts improves surface smoothness, removes tool marks, enhances assembly fit, increases corrosion and wear resistance, and elevates overall appearance.

Brushing

Brushing forms linear textures and is used for electronic product housings.

Powder Coating

Curing after electrostatic spraying provides a variety of colors and wear-resistant surfaces.

Laser Marking

Use laser to engrave information such as marks, text, patterns, etc. on the surface of the material onto the object. Applicable to metal, plastic, ceramic, glass, etc.

Custom Your CNC Machined Stainless Steel Parts, Delivered in 5 Steps

Our streamlined process ensures fast delivery of custom CNC machined Stainless Steel parts for your projects.

Upload Your CAD

Supports STEP, IGES, STL for aluminum CNC machining.

Get Instant Quote

Receive an instant aluminum CNC machining quote online.

DFM Feedback

Optimize designs with our precision aluminum CNC machining expertise.

Precision Machining

Aluminum CNC machining for complex geometries.

Quality Inspection

CMM and 3D scanning ensure tolerances are met.

Fast Delivery

Global fast shipping in 1-7 days.

Proven Success in Stainless Steel CNC Machining for Global Clients

Discover how our custom Stainless Steel CNC machining services deliver precision for leading industries.

Aerospace Turbine Parts

Produced 316 stainless steel turbine parts for an aerospace client, achieving ±0.01mm tolerances and 30% faster delivery.

Medical CNC processed connector medical accessories

Produced from 316L stainless steel for a U.S. medical client. Internal threads, undercuts, polished finish. ISO validated and fast turnaround.

Automotive Parts

Customize large quantities of stainless steel trailer hooks for customers, fast delivery and 15% cost reduction.

Consumer Electronics CNC Aluminum Heat Sink

In order to meet the growing demand for consumer electronics, we provide efficient CNC stainless steel parts machining custom solutions. Whether it’s a coffee machine, a food mixer, etc., our CNC stainless steel machining service can make samples or produce according to your requirements. The attached stainless steel products demonstrate our expertise in CNC machining of small, complex and functional stainless steel parts for electronics.

Applications of CNC Machined Stainless Steel Parts

Our custom Stainless Steel CNC machining service is widely used in many industries, including:

Aerospace

High-strength, corrosion-resistant parts like turbine blades and fasteners.

Medical Devices

Biocompatible stainless steel components for surgical tools and implants.

Automotive & Motorsports

Durable parts for engines, transmissions, and exhaust systems.

Gifts & Crafts

Various models, souvenirs, and doll toys

Energy

Corrosion-resistant components for oil, gas, and renewable energy equipment.

Precision Molding

Injection molds, die casting molds, rubber molds,Micro-structured cavities and complex flow channels

Robotics & Automation

Joint housings, robotic end-effectors, High-precision jigs, fixtures, and toolings

Consumer Electronics

Heat sinks, aluminum enclosures

Stainless Steel CNC Machining & machined parts Gallery

Welcome to our stainless steel photo gallery! Here, you’ll find a visual showcase of our expertise in CNC stainless steel machining.

How Our CNC Stainless Steel Machining Works

As a custom CNC Machining Manufacturer, we provide CNC Machined parts production and rapid prototyping services.

FAQ About CNC Stainless Steel Machining

We offer tolerances as tight as ±0.01mm depending on part geometry and material grade. Learn More

We accept STEP, IGES, PDF, DWG, and DXF files.

Simple parts in 1 day, complex parts in up to 7 days.

Yes. Our MOQ is 1 piece for prototyping.

Yes, we fully support signing a non-disclosure agreement (NDA) with you. All customer drawings will be kept properly and no customer videos or pictures will be forwarded on public platforms. Disassembled drawings are used internally in the factory, and you can split the drawings in advance. The content on the website has been approved by the customer. Please let us know if you have other requirements.

We work with 303, 304, 316, and 410 stainless steels. If you need other types, contact us for consultation.

Yes, we support mass production starting from 200 units per batch.

Available finishes include polishing, brushing, sandblasting, and passivation.

Yes, we specialize in CNC stainless steel machining for rapid prototyping, delivering in 1-3 days.

What Our Clients Say

“We’ve sourced custom stainless steel parts from this team for over 2 years. Their machining quality and consistency are outstanding — tight tolerances and flawless finishes every time.”

James H.

Automotive Engineer, USA

“Fast response, excellent communication, and on-time delivery. Their CNC stainless steel components passed all our inspections without a single issue.”

Clara L.

Procurement Manager, Germany

“From prototype to production, they provided full support and professional advice. The final parts fit perfectly and required no post-processing. A reliable CNC partner!”

Tom S.

Product Developer, UK

Start Your Stainless Steel Parts CNC Machining!

Upload your CAD file for a free quote in 2 hours. Trusted by clients in 60+ countries.