What is Precision CNC Machining?

Precision CNC Machining refers to high-accuracy, computer-controlled manufacturing processes that produce complex metal and plastic parts with tight tolerances—typically within ±0.005mm. Using advanced multi-axis CNC milling, turning, and drilling equipment, we deliver components that meet strict industry standards for quality and repeatability.

Our precision machining services are ideal for prototypes and production parts used in industries such as Aerospace, Medical, Automotive, Electronics, and Robotics. We work with materials like Aluminum, Stainless steel, Titanium, and Engineering plastics, and offer full inspection reports, surface finishing, and Fast global delivery.

Why Choose Our Precision CNC Machining Services?

Our Precision CNC machines provide high-quality machined parts for prototyping and CNC machining batch production, tailored to meet your needs.

Rapid Delivery

Prototypes in 24 hours, production in 3-7 days. In-house CNC machining, milling, turning, drilling, tapping

Extreme Precision

Tolerances as tight as ±0.0002” (±0.005mm).

50+ Materials

Over 50 metals and plastics, including aluminum, stainless steel, titanium, and PEEK.

Custom Solutions

3/4/5-axis CNC machining for intricate designs. Custom CNC machining for complex geometries and unique designs.

Batch Production

Efficient CNC batch production for automotive and electronics.

Your One-Stop Custom Precision CNC Machining Solution

Advanced Precision CNC Machining Capabilities

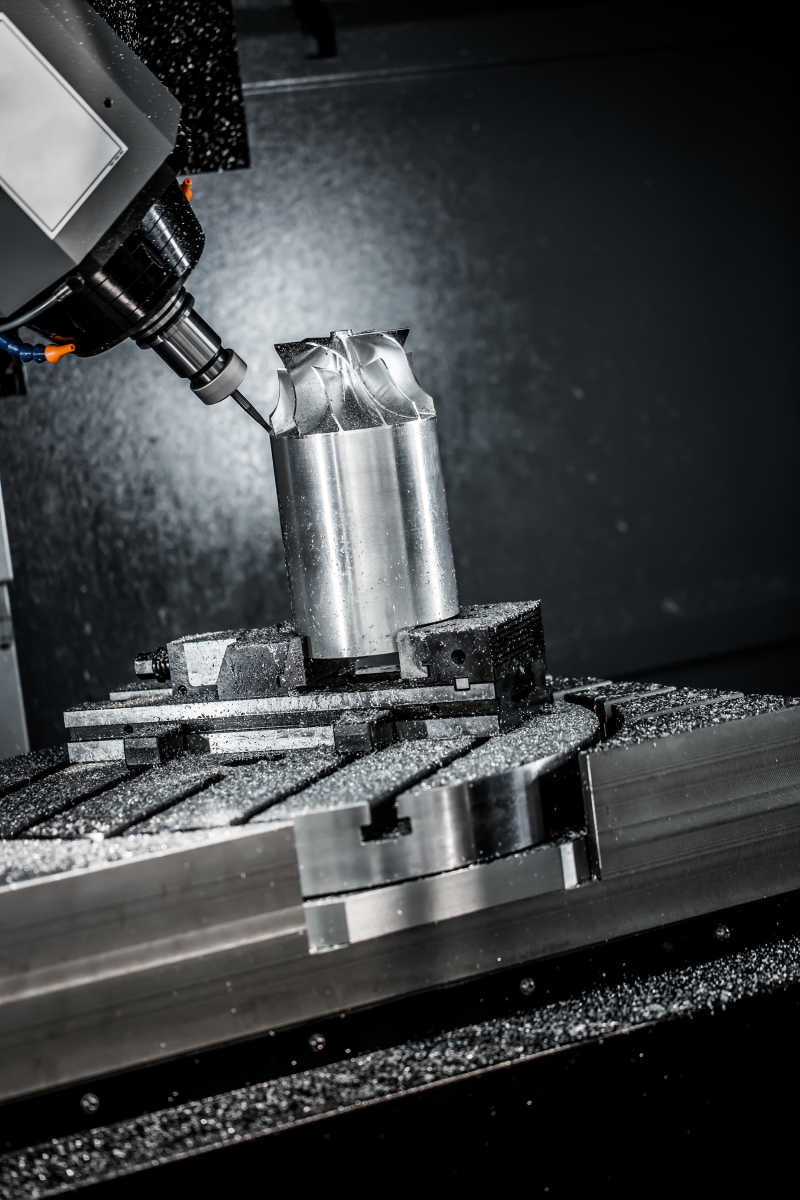

5 Axis CNC Machining Center

5-axis machine Ideal for complex geometries and curved surfaces, especially in aerospace and automotive components.

✅Main advantages: High accuracy, fewer setups, excellent for aerospace and medical parts.

✅Best for: Complex curved surfaces, undercuts, multi-face components

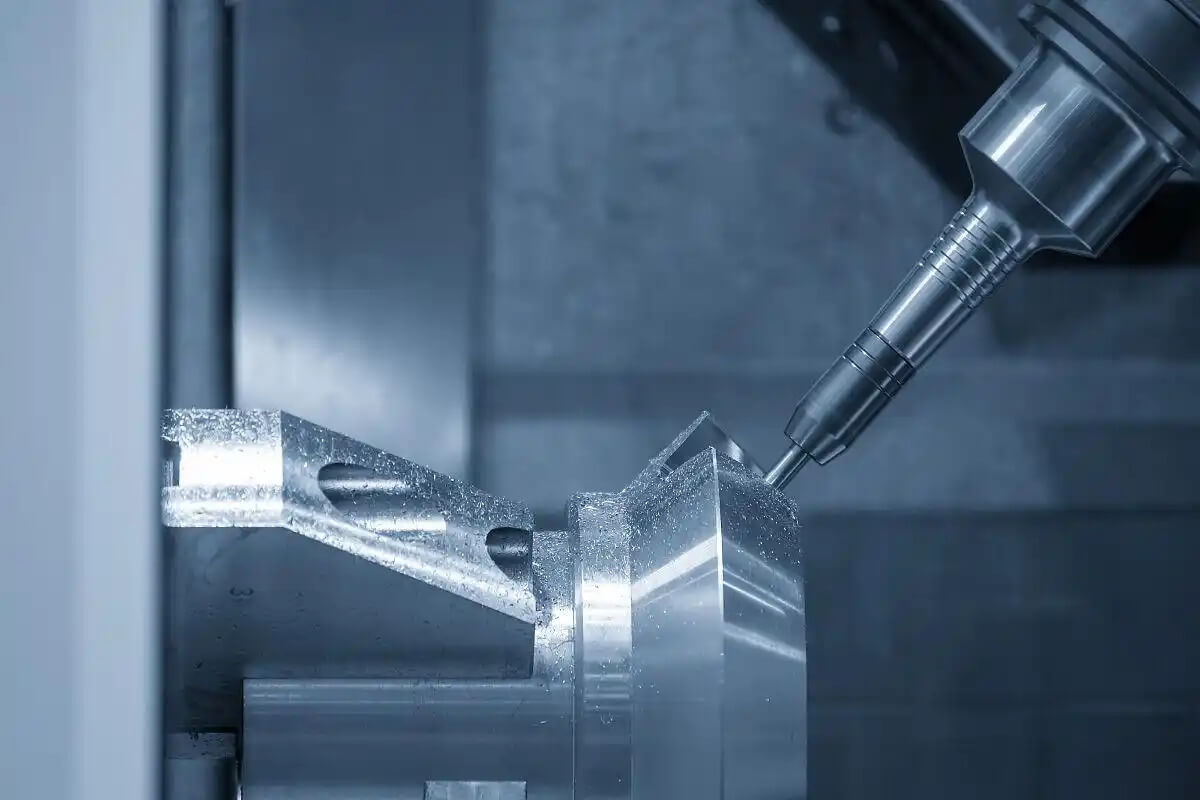

3+2 Axis CNC Machining Center

Economical precision for parts with angled features. Efficient for low- to medium-volume production.

✅ Main advantages: Cost-effective alternative to full 5-axis machining.

✅Best for: Parts requiring angled features without full simultaneous motion.Cost-effective machining parts.

CNC Milling

Accurate machining of slots, pockets, and flat surfaces with excellent repeatability.

✅Main advantages: High-speed, tight tolerance, versatile material compatibility.

✅Best for: Precision housings, structural components, brackets.

CNC Lathes (Turning Centers)

High-speed production of cylindrical and threaded parts such as shafts and bushings.

✅ Main advantages: Excellent for cylindrical parts and high-volume production.

✅ Best for: Shafts, bushings, fasteners, fittings

CNC Drilling Machines

Precise hole-making with consistent depth and tight tolerance for functional assemblies.

✅Main advantages: Consistent hole depth and diameter, tight tolerance control.

✅Best for: Bolt holes, tapped holes, deep hole drilling.

Materials for Precision CNC Machining

According to your design requirements, we have a variety of different CNC materials for you to choose from to meet your customized Precision CNC machining needs. From high-precision metals to engineering plastics, our Precision CNC machining team ensures that each material can achieve perfect processing results.

| Material Type | Examples | Applications |

| Metals | Aluminum (6061, 7075), Titanium, Stainless Steel (304, 316), steel (1045, 4140), copper | Aerospace, Automotive |

| Plastics | ABS, POM, Nylon, PEEK, Acrylic for plastic CNC Milling. | Medical, Electronics |

| Composites | Carbon Fiber | Energy, Aerospace |

Aluminum

Stainless Steel

Titanium

Brass

ABS

Carbon Fiber

Polycarbonate

Acrylic

Engineering Plastics

Custom Precision CNC Machining Surface Finishing Options

We provide a wide range of surface finishing solutions to improve the performance and aesthetics of CNC machined parts. These finishes enhance properties such as texture, hardness, smoothness, chemical resistance, and corrosion resistance. In addition to improving functionality, they effectively conceal tool marks left by the machining process, resulting in a clean, high-quality appearance. Below are some of the most commonly used finishing options:

As Machined

CNC machined metal, natural color, no need for any surface treatment.

Sand Blasting

Cleans the CNC Machining Parts surface and increases the roughness to improve the adhesion of the coating.

Electropolishing

Smooths the surface through electrochemical dissolution, suitable for parts with complex shapes.

Anodizing + Dyeing

Used for surface treatment of metal materials such as aluminum alloy to enhance their decorative properties and corrosion resistance.

Anodizing

Applicable to aluminum-titanium-magnesium alloys, forming an oxide film to enhance corrosion resistance and hardness, such as hard oxidation (Type III) for aviation parts.

Passivation

Make the surface of CNC machined metal parts inactive, thereby slowing down the corrosion rate of the metal.

Polishing

Polishing CNC machined parts improves surface smoothness, removes tool marks, enhances assembly fit, increases corrosion and wear resistance, and elevates overall appearance.

Brushing

Brushing forms linear textures and is used for electronic product housings.

Powder Coating

Curing after electrostatic spraying provides a variety of colors and wear-resistant surfaces.

Laser Marking

Use laser to engrave information such as marks, text, patterns, etc. on the surface of the material onto the object. Applicable to metal, plastic, ceramic, glass, etc.

Your Precision CNC Machining Parts, Delivered in 5 Steps

Our streamlined process ensures fast delivery of custom Precision CNC machined parts for your projects.

Upload Your CAD

Supports STEP, IGES, STL for Precision CNC Machining.

Get Instant Quote

Receive an instant Precision CNC Machining quote online.

DFM Feedback

Optimize designs with our precision CNC machining expertise.

Precision Truning

Precision CNC Machining for complex geometries.

Quality Inspection

CMM and 3D scanning ensure tolerances are met.

Fast Delivery

Global fast shipping in 1-7 days.

Proven Success in Precision CNC Machining for Global Clients

Discover how our custom CNC machining services deliver precision for leading industries.

Precision CNC Machined Scroll Plate Assembly for EV Automotive A/C Compressors

We machined both orbiting and fixed scroll plates from high-strength aluminum alloy for a leading EV air conditioning system supplier. The components required ±0.008mm tolerance and featured complex curved profiles, all completed using 5-axis CNC milling and full inspection.

5-Axis CNC Machined Turbine Blades for Aerospace Engines

This custom-designed aluminum turbo blade was manufactured using advanced 5-axis CNC machining. With complex multi-angle surfaces and tight curvature, the part achieved ±0.008mm tolerance. Ideal for high-performance engines, the finished part was bead-blasted and anodized for enhanced heat resistance and durability.

CNC Machined Titanium Bone Plates for Orthopedic Implants

We partnered with a European orthopedic company to produce custom titanium bone plates using precision 5-axis CNC machining. The implants required ±0.005mm tolerance and mirror-polished surfaces to meet medical-grade biocompatibility standards. All components passed ISO 13485 validation and were individually inspected.

Precision CNC Machining for Your Industry

We provide Precision CNC machined components for various industries, including:

Aerospace

Turbine blades, engine housings, structural components. Landing gear parts, wing fittings, Satellite and UAV precision components

Medical Devices

Orthopedic implants (e.g., knee and hip replacements). Surgical instruments, dental tools. Customized prosthetics and medical fixtures

Automotive & Motorsports

Engine components, transmission housings. Injection mold tooling for interiors/exteriors. High-performance and motorsport parts.

Gifts & Crafts

Various models, souvenirs, and doll toys

Energy

Gas turbine parts, wind turbine blade molds, Drilling equipment components, nuclear power parts

Precision Molding

Injection molds, die casting molds, rubber molds,Micro-structured cavities and complex flow channels

Robotics & Automation

Joint housings, robotic end-effectors, High-precision jigs, fixtures, and toolings

Consumer Electronics

Heat sinks, connectors, structural housings, Precision frames for smartphones and smart devices

Precision CNC Machining & machined parts Gallery

Below is a small selection of Precision CNC Machining and end-use precision machined parts we produce for our customers. Used with permission.

How Our Precision CNC Machining Works

As a custom CNC turning manufacturer, we provide CNC turned parts production and rapid prototyping services.

Frequently Asked Questions About Precision CNC Machining

Standard tolerance is ±0.05mm, with precision options down to ±0.01mm upon request.

We accept STEP, IGES, PDF, DWG, and DXF files.

Simple parts in 1 day, complex parts in up to 7 days.

Yes. Our MOQ is 1 piece for prototyping.

Yes, we fully support signing a non-disclosure agreement (NDA) with you. All customer drawings will be kept properly and no customer videos or pictures will be forwarded on public platforms. Disassembled drawings are used internally in the factory, and you can split the drawings in advance. The content on the website has been approved by the customer. Please let us know if you have other requirements.

We offer over 50 metals and plastics, including aluminum, titanium, PEEK, and ABS.

Yes. We offer anodizing, powder coating, polishing, sandblasting, plating, etc.

Yes, we machine plastics like ABS, POM, PEEK, and acrylic with high precision.

Yes, we specialize in CNC machined aluminum for rapid prototyping, delivering in 1-3 days.

What Our Clients Say

“We’ve been sourcing custom CNC machined aluminum parts from this supplier for over a year. The precision machining quality and fast turnaround time always exceed expectations. Their 5-axis capabilities are crucial for our turbo housing prototypes. Highly recommended!”

Markus H.

Automotive Engineering Lead, Germany

“Excellent communication and consistent quality. Their ability to deliver tight tolerance CNC turned parts in medical-grade stainless steel helped us accelerate our product validation. Everything was packaged with care and certification included.”

Sarah L.

Procurement Director, USA

“As a startup, we needed a reliable partner for rapid CNC prototyping and low-volume production. The parts arrived in 5 days and looked flawless. Their online quote process and DFM feedback saved us time and cost.”

Jonathan K.

CEO, UK

Start Your Precision CNC Maching Project Today

Upload your CAD file for a free quote in 2 hours. Trusted by clients in 60+ countries.